Jinhua Yosocoma Technology Co., Ltd. locates in Jinhua city of Zhejiang Province, which is a custom Aluminum alloy rim -WR factory and wholesale Aluminum alloy rim -WR manufacturers , mainly used for Motocross, Supermotard, and other motorcycles on road or off road. We are main enterprise in Chinese motorcycle industry, over 100 staff working in our factory, annual sales volume over RMB 30 Million.

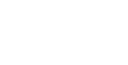

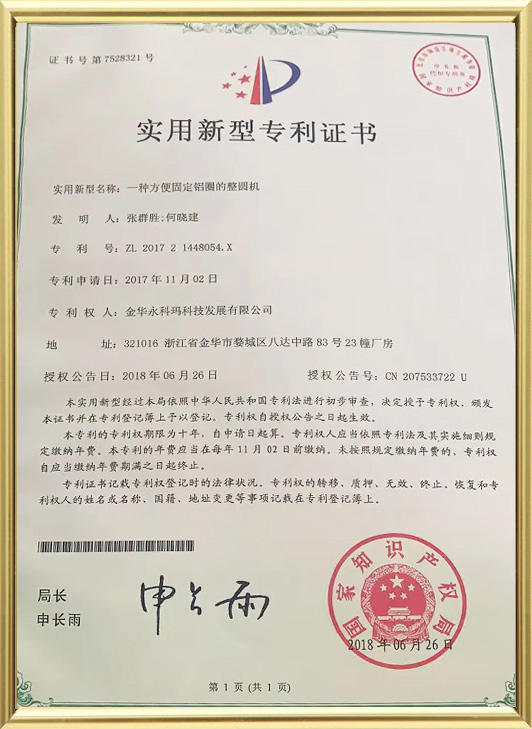

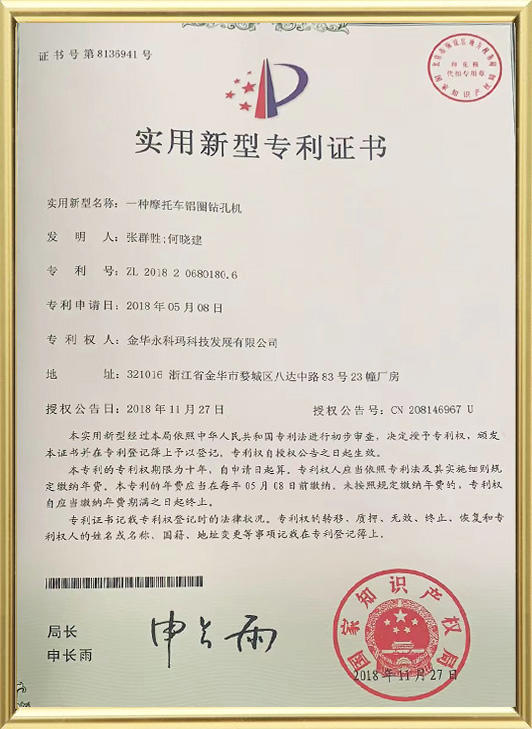

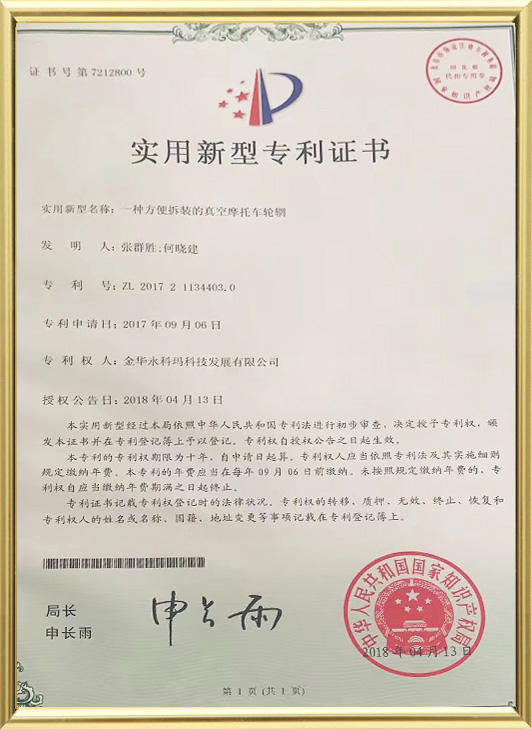

Our company holds complete advanced processing equipments, excellent technology teams, we are honored with ISO9001 Quality System Certification, China Industrial Standard Testing Certification, and DOT Certification of America, We always commit ourselves to improve machining equipments, processing technology, and continually to complete production testing to meet international high quality standard.

WR Type Aluminum Alloy Rim Producers

Company Profile

News

-

Riding in Style: Durable Stainless Steel Motorcycle Rims

OEM 17 Inch Stainless Steel Motorcycle Rims Price For Sale Motorcycle enthusiasts understand that every ...

READ MORE -

The Appeal of Durable Stainless Steel Motorcycle Rims

Wholesale Custom 17 Inch Stainless Steel Motorcycle Rims Motorcycle enthusiasts understand that every co...

READ MORE -

Stainless Steel Motorcycle Rims for Speed and Safety

China Sale 17 Inch Stainless Steel Motorcycle Rims Supplier In the realm of motorcycles, where speed, pr...

READ MORE -

Strength and Aesthetics: Stainless Steel Motorcycle Rims

17 Inch Stainless Steel Motorcycle Rims Manufacturer Factory In the world of motorcycles, every componen...

READ MORE -

Stainless Steel Motorcycle Rims: A Guide to Performance and Aesthetics

17 Inch Stainless Steel Motorcycle Rims Price For Sale Maker The motorcycle world is a blend of art and ...

READ MORE

Industry Knowledge Exhibition

In the dynamic world of motorcycle customization, the choice of wheel rims plays a pivotal role in determining the overall aesthetics and performance of the bike. Two notable innovations in this realm are the WR Type Aluminum Alloy Rim, renowned for its advanced casting techniques, and the Color Size Forged Alloy Wheel Rim, a diverse range that caters to individual preferences.

Casting Techniques for WR Type Aluminum Alloy Rim

The WR Type Aluminum Alloy Rim stands as a testament to precision engineering and advanced casting techniques. Here are key considerations in the casting process:

Gravity Die Casting:

Gravity die casting is a widely used technique in crafting WR Type Rims. This method involves pouring molten aluminum into a permanent mold using gravity. The mold is carefully designed to replicate the intricate details of the rim, ensuring a precise and consistent final product.

Low-Pressure Casting:

Low-pressure casting is another technique employed for WR Type Rims. In this process, molten aluminum is injected into the mold at a lower pressure, reducing turbulence and enhancing the structural integrity of the rim. The result is a wheel with improved density and strength.

Heat Treatment:

The WR Type Rim undergoes heat treatment to further enhance its mechanical properties. This process involves controlled heating and cooling to optimize the alloy's strength and hardness, ensuring that the rim can withstand the demands of various riding conditions.

Machining and Finishing:

After the casting process, the rim undergoes precision machining to achieve the desired specifications. The final step involves finishing processes such as polishing, painting, or coating to enhance the rim's visual appeal and protect it from corrosion.

Different Types of Aluminum Alloys Used for Color Size Forged Alloy Wheel Rim

Color Size Forged Alloy Wheel Rims offer a wide range of options, not just in terms of design but also in the types of aluminum alloys used. Each alloy brings unique characteristics to the table:

Aluminum Alloy 6061:

Known for its excellent strength-to-weight ratio, 6061 aluminum alloy is a popular choice for forged wheel rims. It offers outstanding durability and is resistant to corrosion, making it ideal for riders who seek a balance of performance and longevity.

Aluminum Alloy 7075:

Renowned for its high strength and toughness, 7075 aluminum alloy is often used in the construction of high-performance Color Size Forged Alloy Wheel Rims. This alloy is particularly favored in applications where ascendant strength and weight reduction are critical factors.

Aluminum Alloy 5083:

Color Size Forged Alloy Wheel Rims crafted from 5083 aluminum alloy excel in corrosion resistance, especially in marine environments. This makes them suitable for riders who frequently encounter harsh weather conditions or ride in coastal areas.

Aluminum Alloy 2024:

Known for its exceptional fatigue resistance, 2024 aluminum alloy is a popular choice for Color Size Forged Alloy Wheel Rims intended for heavy-duty applications. Riders who engage in long-distance touring or off-road adventures often appreciate the reliability and endurance provided by this alloy.

WR Type Aluminum Alloy Rim, with its advanced casting techniques, and the Color Size Forged Alloy Wheel Rim, with its diverse range of aluminum alloys, represent the epitome of customization in the motorcycle industry. The precision in casting techniques ensures the WR Type Rim's performance and durability, while the variety of aluminum alloys in Color Size Forged Alloy Wheel Rims caters to riders with distinct preferences and priorities. As motorcycle enthusiasts seek to express their individuality on the road, these innovations pave the way for a future where style and substance seamlessly come together on two wheels.

English

English Español

Español

浙公网安备33071802889078

浙公网安备33071802889078