Jinhua Yosocoma Technology Co., Ltd. locates in Jinhua city of Zhejiang Province, which is a custom Aluminum alloy rim -K factory and wholesale Aluminum alloy rim -K manufacturers , mainly used for Motocross, Supermotard, and other motorcycles on road or off road. We are main enterprise in Chinese motorcycle industry, over 100 staff working in our factory, annual sales volume over RMB 30 Million.

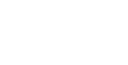

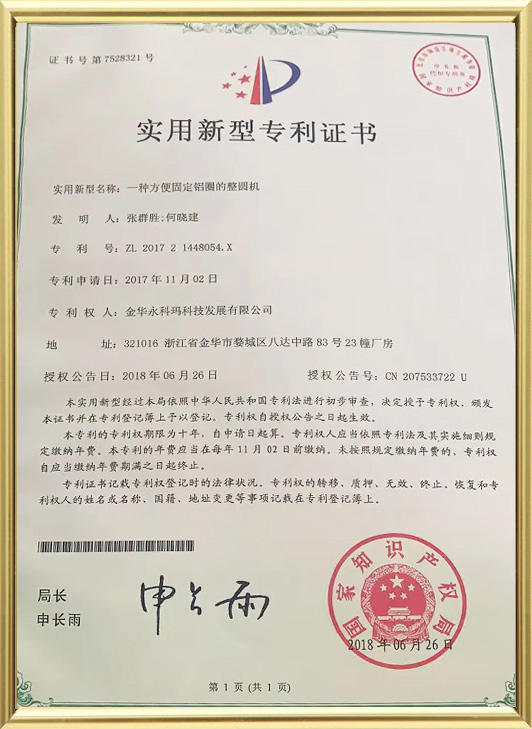

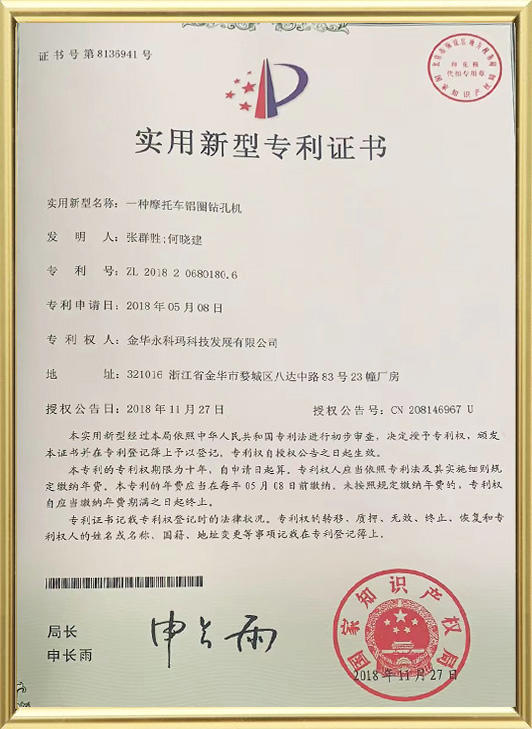

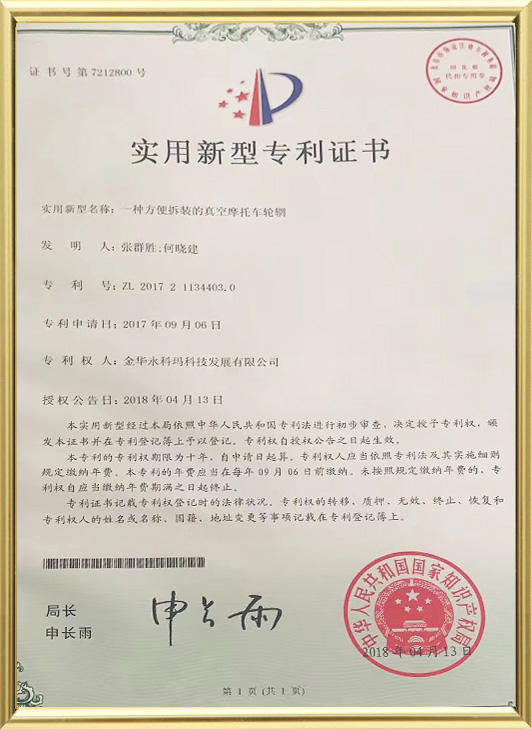

Our company holds complete advanced processing equipments, excellent technology teams, we are honored with ISO9001 Quality System Certification, China Industrial Standard Testing Certification, and DOT Certification of America, We always commit ourselves to improve machining equipments, processing technology, and continually to complete production testing to meet international high quality standard.

K Type Aluminum Alloy Rim Wholesalers

Company Profile

News

-

The Art of Performance: How Stainless Steel Spokes Enhance Your Motorcycle

Cheap Stainless Steel Colored Motorcycle Spokes Maker in China The motorcycle, a symbol of freedom and a...

READ MORE -

Understanding the Importance of Stainless Steel Spokes

Stainless Steel Colored Motorcycle Spokes Price OEM Company When it comes to motorcycle design and maint...

READ MORE -

Durable and Dazzling: The Benefits of Stainless Steel Motorcycle Spokes

Wholesale Custom Colored Stainless Steel Motorcycle Spokes Supplier Motorcycles are a blend of mechanica...

READ MORE -

Strength and Style: The Allure of Stainless Steel Motorcycle Spokes

China Stainless Steel Colored Motorcycle Spokes Manufacturer Factory Motorcycles are a symbol of freedom...

READ MORE -

Exploring High-Performance Stainless Steel Motorcycle Rims

17 Inch Stainless Steel Motorcycle Rims Maker in China Wholesaler In the world of motorcycles, every com...

READ MORE

Industry Knowledge Exhibition

In the realm of motorcycle and light vehicle customization, the wheel rim stands as a critical component, influencing both performance and aesthetics.

Fatigue Properties and Longevity of K Type Aluminum Alloy Rim

The K Type Aluminum Alloy Rim is engineered to withstand the demanding conditions of road travel. Let's examine the key factors that contribute to its exceptional fatigue properties and longevity:

Material Selection:

The choice of aluminum alloy in the construction of the K Type Rim plays a crucial role in determining its fatigue resistance. These rims often utilize high-quality alloys known for their excellent strength-to-weight ratios, such as 6061 or 7075 aluminum. This ensures durability without compromising on weight.

Optimized Design:

The design of the K Type Rim undergoes careful consideration to distribute stress evenly across the structure. By minimizing stress concentrations, the rim can endure the cyclic loading experienced during rides without succumbing to fatigue, contributing to its long-term reliability.

Heat Treatment:

Many K Type Rims undergo heat treatment processes that further enhance their fatigue resistance. Controlled heating and cooling cycles optimize the material properties, making the rim more resilient to the constant stresses it encounters on the road.

Quality Manufacturing Standards:

Rigorous manufacturing standards and quality control measures ensure that each K Type Rim meets or exceeds industry expectations. This commitment to excellence contributes to the overall longevity of the rim, providing riders with a reliable and durable component for their vehicles.

Surface Treatments and Finishes Applied to Aluminum Light Vehicle Wheels Rim

The surface treatments and finishes applied to Aluminum Light Vehicle wheel rims go beyond mere aesthetics; they serve as protective layers, enhancing durability and appearance:

Painting and Powder Coating:

Painting and powder coating are popular surface treatments for aluminum rims. These methods not only add vibrant colors and intricate designs but also create a protective barrier against environmental elements, preventing corrosion and enhancing the overall lifespan of the rim.

Anodization:

Anodization is a specialized surface treatment that involves creating a durable oxide layer on the aluminum surface. This layer not only adds corrosion resistance but also provides a base for vibrant color options. Anodized rims are known for their durability and long-lasting appearance.

Polishing and Machining:

For a sleek and high-gloss finish, rims may undergo polishing and machining processes. These treatments not only enhance the visual appeal but also contribute to the removal of surface imperfections, promoting a smoother and more resistant surface against wear and tear.

Clear Coating:

Clear coating is often applied to aluminum rims to protect the surface from oxidation and maintain the original shine. This transparent layer acts as a shield, preventing environmental factors from affecting the integrity of the rim's appearance.

K Type Aluminum Alloy Rim proves its mettle through advanced engineering that prioritizes fatigue resistance and longevity. Its robust construction ensures that riders can trust their wheels to endure the challenges of the road. Complementing this durability is the artistry of surface treatments and finishes applied to Aluminum Light Vehicle wheel rims. Beyond visual enhancements, these treatments act as guardians, preserving the rim's structural integrity and enhancing its overall lifespan. As the world of customization continues to evolve, the marriage of durability and design in wheel technology remains a testament to the ingenuity driving the future of automotive aesthetics and performance.

English

English Español

Español

浙公网安备33071802889078

浙公网安备33071802889078