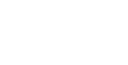

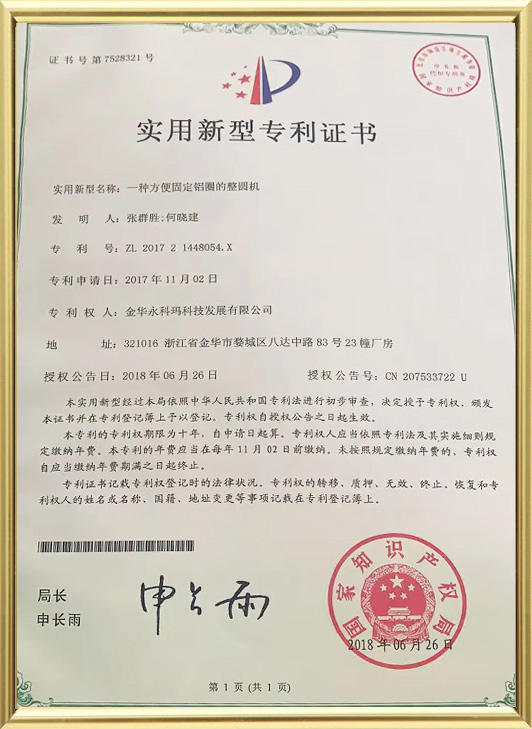

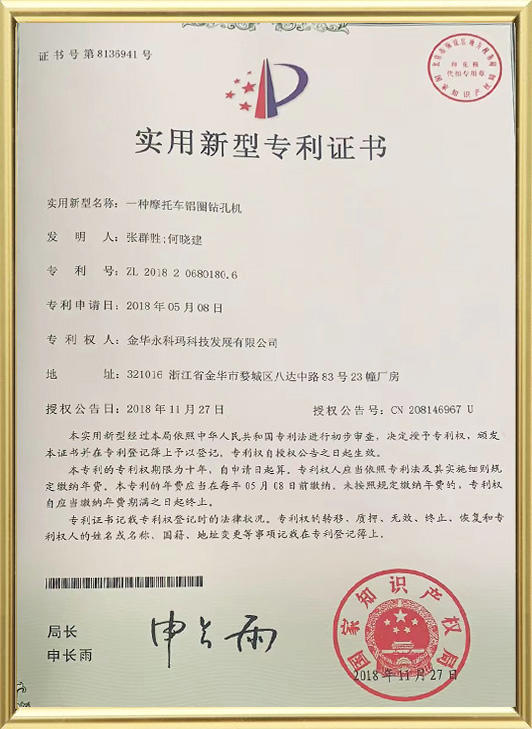

Jinhua Yosocoma Technology Co., Ltd. locates in Jinhua city of Zhejiang Province, which is a custom Aluminum alloy rim -U factory and wholesale Aluminum alloy rim -U manufacturers , mainly used for Motocross, Supermotard, and other motorcycles on road or off road. We are main enterprise in Chinese motorcycle industry, over 100 staff working in our factory, annual sales volume over RMB 30 Million.

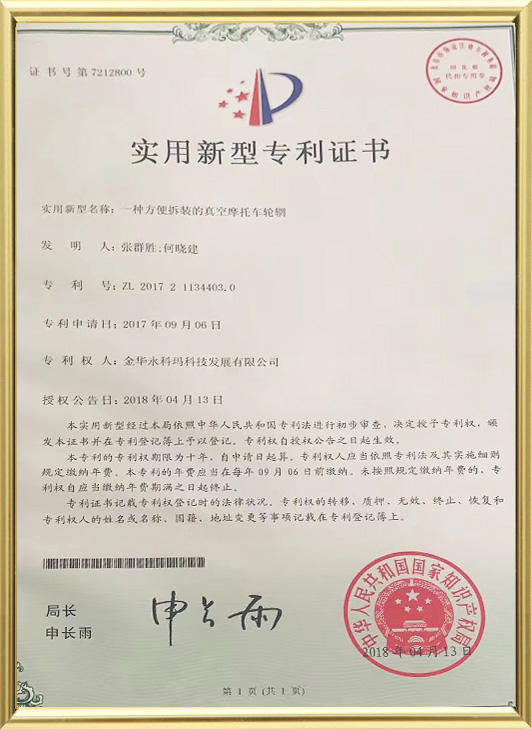

Our company holds complete advanced processing equipments, excellent technology teams, we are honored with ISO9001 Quality System Certification, China Industrial Standard Testing Certification, and DOT Certification of America, We always commit ourselves to improve machining equipments, processing technology, and continually to complete production testing to meet international high quality standard.

High Quality U Type Aluminum Alloy Rim

Company Profile

News

-

Riding in Style: Durable Stainless Steel Motorcycle Rims

OEM 17 Inch Stainless Steel Motorcycle Rims Price For Sale Motorcycle enthusiasts understand that every ...

READ MORE -

The Appeal of Durable Stainless Steel Motorcycle Rims

Wholesale Custom 17 Inch Stainless Steel Motorcycle Rims Motorcycle enthusiasts understand that every co...

READ MORE -

Stainless Steel Motorcycle Rims for Speed and Safety

China Sale 17 Inch Stainless Steel Motorcycle Rims Supplier In the realm of motorcycles, where speed, pr...

READ MORE -

Strength and Aesthetics: Stainless Steel Motorcycle Rims

17 Inch Stainless Steel Motorcycle Rims Manufacturer Factory In the world of motorcycles, every componen...

READ MORE -

Stainless Steel Motorcycle Rims: A Guide to Performance and Aesthetics

17 Inch Stainless Steel Motorcycle Rims Price For Sale Maker The motorcycle world is a blend of art and ...

READ MORE

Industry Knowledge Exhibition

Navigating the Design Considerations for U Type Aluminum Alloy Rims

In the dynamic world of motorcycle design, every component plays a crucial role in determining performance, aesthetics, and overall riding experience. Two key innovations that have redefined the landscape are U Type Aluminum Alloy Rims and 36-Hole Aluminum Alloy Rims.

Design Considerations for U Type Aluminum Alloy Rim

The U Type Aluminum Alloy Rim represents a pinnacle in wheel engineering, with design considerations aimed at achieving the good balance between form and function.

Aerodynamic Efficiency:

The streamlined shape of the U Type Rim is not merely for visual appeal—it is a result of careful consideration of aerodynamics. The design minimizes air resistance, allowing the motorcycle to cut through the air with reduced drag, ultimately enhancing fuel efficiency and overall speed.

Weight Optimization:

Engineers meticulously analyze material properties to strike a balance between strength and weight. The U Type Aluminum Alloy Rim is crafted to be lightweight without compromising structural integrity, contributing to improved handling and maneuverability.

Heat Dissipation:

As brakes generate heat during operation, effective heat dissipation is crucial for maintaining ideal performance. The U Type Rim is designed to facilitate efficient heat dissipation, ensuring that the braking system remains cool under demanding conditions.

Structural Rigidity:

The U Type Rim undergoes rigorous stress testing to guarantee structural rigidity. This ensures that the rim can withstand the dynamic forces encountered during various riding conditions, providing stability and safety to the rider.

Visual Appeal:

Beyond performance considerations, the U Type Rim is designed with an eye for aesthetics. The sleek curves and modern finish contribute to the overall visual appeal of the motorcycle, making it a statement piece on the road.

36 Development of Hole Aluminum Alloy Rim

The development of the 36-Hole Aluminum Alloy Rim introduces a fascinating chapter in the evolution of motorcycle wheel technology. This design reflects a strategic approach to distributing stress and optimizing performance.

Even Load Distribution:

The 36-hole configuration is carefully calculated to evenly distribute the load across the rim. This not only enhances the overall strength of the wheel but also reduces the risk of localized stress points, which can lead to premature wear and tear.

Enhanced Stability:

The placement of 36 holes is strategically chosen to maximize stability. By distributing the load more evenly, the rim contributes to improved stability, particularly during high-speed rides or when navigating challenging terrains.

Customization Possibilities:

The 36-hole design allows for greater customization options. Riders can choose different spoke patterns and lacing styles, enabling them to personalize their motorcycles according to their preferences while maintaining the structural integrity of the wheel.

Durability Under Stress:

The 36-hole configuration is a testament to the commitment to durability. Whether tackling off-road trails or cruising on highways, the design ensures that the rim can withstand the diverse stresses encountered during various riding conditions.

Compatibility with Advanced Tire Technologies:

As tire technologies continue to evolve, the 36-hole rim remains compatible with a wide range of tire options. This adaptability ensures that riders can take advantage of the latest innovations in tire design without compromising the integrity of their wheels.

The design considerations behind the U Type Aluminum Alloy Rim and the development of the 36-Hole Aluminum Alloy Rim showcase the intersection of engineering precision and innovation in the world of motorcycle wheels. Embrace the future of motorcycle wheel technology, where form meets function in a seamless dance of design excellence.

English

English Español

Español

浙公网安备33071802889078

浙公网安备33071802889078